LYNCA – CNC

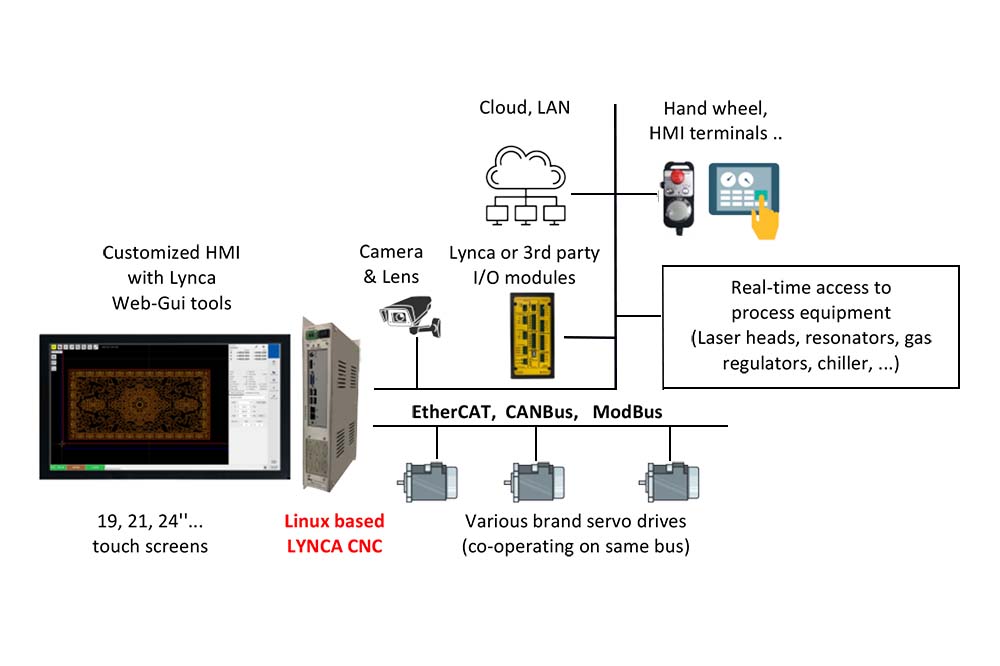

PC based open architecture CNC control solution specialized for customized multi-axis machines.

LYNCA – CNC is a cost-efficient solution that may be used in many application as a plug and play product.

LYNCA – CNC applications for laser and plasma cutting machines are available with CYBELEC hardware (displays and I/O modules) under the CYBELEC – LYNCA brand